PC312 User Manual: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1,384: | Line 1,384: | ||

[[File:Modbus Configuration.png|frameless|620x620px]] | [[File:Modbus Configuration.png|frameless|620x620px]] | ||

'''Parameter Configuration:''' | |||

As shown in the image below, there are two types of protocol used in Modbus configuration. | |||

1.) RTU (Remote Terminal Unit) | |||

2.) TCP (Transmission Control Protocol) | |||

Details of both protocols is mentioned in the specification table. | |||

[[File:Modbus Parameter Configuration.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|DEVICE NAME | |||

|Ex: Invendis | |||

|This is the name assigned to the Modbus device for identification purposes. | |||

|- | |||

|2 | |||

|Port number | |||

|RS485 Port-1 | |||

|This specifies which RS485 port on the device is being used for communication. | |||

|- | |||

|3 | |||

|Meter ID | |||

|1 | |||

|The Meter ID is a unique identifier for the specific meter within the network. Each Modbus device on the network must have a unique ID to differentiate it from others. | |||

|- | |||

|4 | |||

|Meter Model | |||

|Example: abcd | |||

|This field specifies the model of the meter. | |||

|- | |||

|5 | |||

|Function Code | |||

|read coils (1) | |||

read input coils (2) | |||

read holding registers (3) | |||

read input registers (4) | |||

|The function code indicates the operation to be performed. In Modbus, each operation has a specific function code. | |||

|- | |||

|6 | |||

|Slave Address | |||

|Example: '''1''' | |||

|The slave address identifies the specific slave device on the Modbus network. Each slave must have a unique address so that the master can communicate with it individually. | |||

|- | |||

| | |||

| | |||

|'''Modbus protocol: RTU''' | |||

| | |||

|- | |||

|7 | |||

|Baud rate | |||

|<nowiki>300 | 1200 | 1800 | 2400 | 4800 | 19200 | 38400 | default: 9600</nowiki> | |||

|The baud rate determines the communication speed between devices, measured in bits per second. | |||

|- | |||

|8 | |||

|Parity | |||

|1.) NONE | |||

2.) ODD | |||

3.) EVEN | |||

|1.) No parity bit is added to the data byte. | |||

2.) Ensures that the total number of 1-bits in | |||

the data byte plus the parity bit is even. | |||

3.) Ensures that the total number of 1-bits in the data byte plus the parity bit is odd. | |||

|- | |||

|9 | |||

|No. of Databits | |||

|7/8 | |||

|Indicates that 8 data bits are used per byte, which is a common setting. | |||

|- | |||

|10 | |||

|No. of Stopbits | |||

|1/2 | |||

|Configures the serial communication to use 1 stop bit, which is a common setting ensuring the end of each byte is clearly marked. | |||

|- | |||

| | |||

| | |||

|'''Modbus protocol: TCP''' | |||

| | |||

|- | |||

|11 | |||

|Modbus Comm IP | |||

|Ex: 192.168.10.147 | |||

|IP of the device you are communicating with. | |||

|- | |||

|12 | |||

|Modbus Comm Port | |||

|Ex: 502 (default) | |||

|Give a specified TCP port number | |||

|- | |||

|13 | |||

|Modbus Comm Timeout | |||

|Ex: 60 | |||

|This refers to the maximum amount of time the master device will wait for a response from a slave device before it assumes a communication failure. | |||

|- | |||

|14 | |||

|Start Register | |||

|Example: 0 | |||

|The start register indicates the address of the first register to be read in the slave device. | |||

|- | |||

|15 | |||

|No. of Resister | |||

|Example: 10 | |||

|This specifies the number of consecutive registers to read starting from the start register. | |||

|} | |||

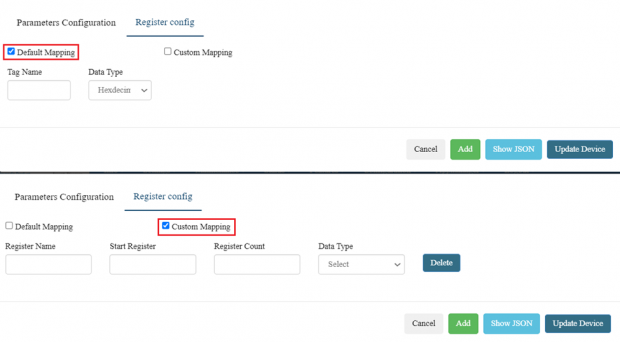

'''Register Config:''' | |||

In this section you can add multiple parameters to read in ‘Default Mapping’ & ‘Custom Mapping’.[[File:Modbus Register Configuration.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Default mapping | |||

|1.) Tag Name = (Ex: FQ) | |||

2.) Data type = Hexadecimal; Floating point| IEEE 754 (Swapped byte) | Floating point (Swapped Byte) | 16bit INT, high byte first | 16bit INT, low byte first | 16bit UINT, high byte first | 16bit UINT, low byte first | 32bit UINT (byte order 1,2,3,4) | 32bit UINT (byte order 4,3,2,1) | 32bit INT (byte order 1,2,3,4) | 32bit INT (byte order 4,3,2,1) | |||

|1.) Input value name. | |||

2.) Defines how read data will be stored. | |||

|- | |||

|2 | |||

|Custom mapping | |||

|1.) Register name: | |||

2.) Start register: | |||

3.) Register count: | |||

4.) Data type =Hexadecimal; Floating point | IEEE 754 (Swapped byte) | Floating point (Swapped Byte) | 16bit INT, high byte first | 16bit INT, low byte first | 16bit UINT, high byte first | 16bit UINT, low byte first | 32bit UINT (byte order 1,2,3,4) | 32bit UINT (byte order 4,3,2,1) | 32bit INT (byte order 1,2,3,4) | 32bit INT (byte order 4,3,2,1) | |||

|1.) Input value name. | |||

2.) First register in custom register block. | |||

3.) Path to file in which the custom register block will be stored. | |||

4.) Defines how read data will be stored. | |||

|} | |||

In Register Config, | |||

Click on ‘Add’ to add new parameters. | |||

Click on ‘Show JSON’ to view an example value of how the data will be presented. Click on ‘Update Device’ once configuration changes have been made. | |||

== 6.3 Data Source Configuration == | |||

These configurations ensure that the system regularly acquires data from various interface like RS485 at specified intervals, allowing for efficient monitoring and management of connected devices and sensors. | |||

[[File:Source Configuration 1.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Enable RS485Line1 | |||

|Enable/Disable | |||

|This option enables the RS485 Line 1 interface for energy meter readings. | |||

|- | |||

|2 | |||

|Overall Periodicity of RS485 Line 1 Energy meter Readings (In Seconds >= 60) | |||

|'''Value:''' 60 | |||

|Defines the interval in seconds at which readings are taken from the RS485 Line 1 energy meter. The minimum allowable interval is 60 seconds. | |||

|- | |||

|3 | |||

|Delay between each Energy meter Readings (in Milliseconds) | |||

|'''Value:''' 2000 | |||

|Specifies the delay in milliseconds between individual readings from the energy meter on RS485 Line 1. | |||

|} | |||

Click on save once changes have been made. | |||

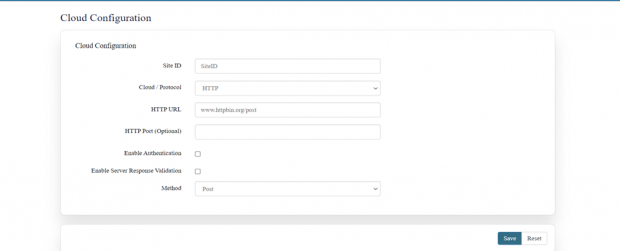

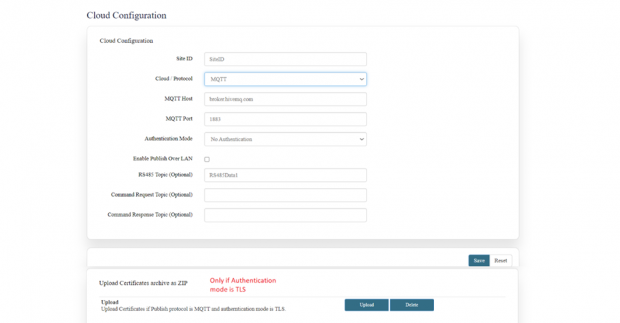

== 6.4 Cloud Configuration == | |||

In this section you can select the protocol by which you need to send data to cloud. | |||

There are 3 Cloud/Protocol available, | |||

'''HTTP''' | |||

'''MQTT''' | |||

'''Azure''' | |||

[[File:Cloud Configuration.png|frameless|620x620px]] | |||

'''HTTP Cloud/Protocol:''' This configuration sets up communication between your device and cloud service using the HTTP cloud. | |||

[[File:HTTP Cloud-Protocol.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Site ID | |||

|Ex: ‘Site123’ or ‘Device456’. | |||

|A unique identifier for your site or device within the cloud service. | |||

|- | |||

|2 | |||

|Cloud / Protocol | |||

|HTTP | |||

|The protocol used for communication with the cloud service. | |||

|- | |||

|3 | |||

|HTTP URL | |||

|'''Example:''' www.httpbin.org/post | |||

|The endpoint URL of the cloud service where data will be sent. | |||

|- | |||

|4 | |||

|HTTP Port (Optional) | |||

|Leave it blank for the default port. | |||

|The port number for the HTTP connection. This is optional because the default port for HTTP (80) is used if not specified. | |||

|- | |||

|5 | |||

|Enable Authentication | |||

|Enable/Disable | |||

|Enable this if your cloud service requires a username and password. | |||

|- | |||

|6 | |||

|Username | |||

|'''Example:''' admin | |||

|The username for authentication with the cloud service. | |||

|- | |||

|7 | |||

|Password | |||

|***** | |||

|The password for authentication with the cloud service. | |||

|- | |||

|8 | |||

|Enable Server Response Validation | |||

|Enable/Disable | |||

|Enable this if you need to verify that the server's response is valid. | |||

|- | |||

|9 | |||

|Server Response | |||

|Ex: RecordID or custom | |||

|A unique identifier for the record being sent to the cloud service. | |||

|- | |||

|10 | |||

|Method | |||

|1.) Post | |||

2.) Get | |||

|1.) The HTTP method used for sending data to the cloud service. | |||

2.) The HTTP method used for requesting data from the cloud service. | |||

|} | |||

'''MQTT Cloud/Protocol:''' | |||

This configuration sets up communication between your device and a cloud service using the MQTT protocol.[[File:MQTT Cloud-Protocol.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Site ID | |||

|Example: ‘Site123’ or ‘Device456’. | |||

|A unique identifier for your site or device within the cloud service. | |||

|- | |||

|2 | |||

|Cloud / Protocol | |||

|MQTT | |||

|The protocol used for communication with the cloud service. | |||

|- | |||

|3 | |||

|MQTT Host | |||

|'''Example:''' broker.hivemq.com | |||

|The MQTT broker's address (hostname or IP address) that the device will connect to for sending and receiving messages. | |||

|- | |||

|4 | |||

|MQTT Port | |||

|'''Example:''' 1883 | |||

|This is the default port for unencrypted MQTT connections. | |||

|- | |||

|5 | |||

|Authentication Mode | |||

|1.) No Authentication | |||

2.) Username/Password | |||

3.) TLS | |||

|1.) Connect to the broker without any credentials. | |||

2.) The Username/Password for authentication with the cloud service. | |||

3.) Upload TLS certificates only if TLS authentication is selected as shown in the above image. | |||

|- | |||

|6 | |||

|Enable Publish Over LAN | |||

|Enable/Disable | |||

|When enabled, the device will also publish MQTT messages over the local area network (LAN). | |||

|- | |||

|7 | |||

|RS485 Topic (Optional) | |||

|'''Example:''' RS485Data1 | |||

|The MQTT topic for publishing RS485 data. | |||

|- | |||

|8 | |||

|Command Request Topic (Optional) | |||

|'''Example:''' CommandRequest1 | |||

|The topic to which the device listens for command requests. Leave it blank if not in use. | |||

|- | |||

|9 | |||

|Command Response Topic (Optional) | |||

|'''Example:''' CommandResponse1 | |||

|The topic on which the device publishes responses to commands. Leave it blank if not in use. | |||

|} | |||

Click on save once configuration changes have been made. | |||

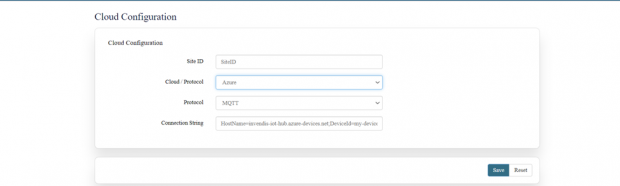

'''Azure:''' | |||

This configuration sets up the connection to Azure IoT Hub using either MQTT or HTTP protocols with a specified connection string. | |||

[[File:Azure Configuration.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Site ID | |||

|Example: ‘Site123’ or ‘Device456’. | |||

|A unique identifier for your site or device within the cloud service. | |||

|- | |||

|2 | |||

|Cloud / Protocol | |||

|Azure | |||

|The cloud service and protocol used for communication. | |||

|- | |||

|3 | |||

|Protocol | |||

|1.) MQTT | |||

2.) HTTP | |||

|1.) A lightweight messaging protocol suitable for IoT devices. | |||

2.) A protocol used for communication over the web, commonly used for RESTful services. | |||

|- | |||

|4 | |||

|Connection String | |||

|e.g., invendis-iot-hub.azure-devices.net. | |||

|The primary or secondary key used to authenticate the device with the IoT Hub. | |||

|} | |||

Click on save once configuration changes have been made | |||

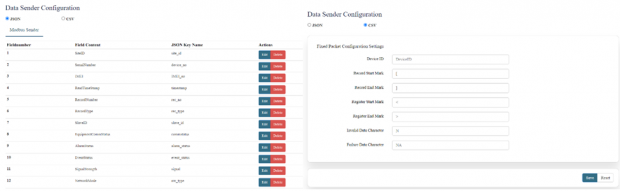

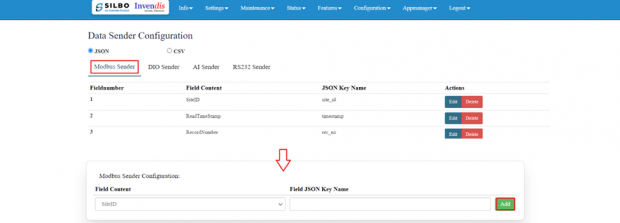

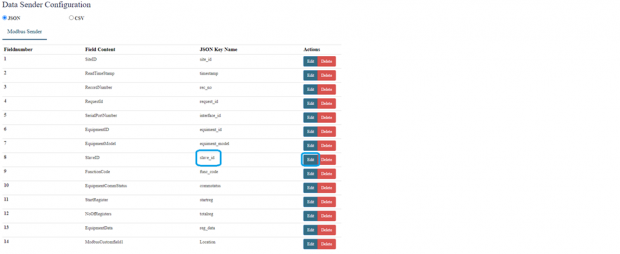

== 6.5 Send Configuration == | |||

Send configuration allows to choose type of string that should be sent to a cloud platform. | |||

SILBO devices do offer 3 different options as shown below. | |||

CSV (CSV allows fixed CSV) | |||

Fixed JSON | |||

Editable JSON. (JSON option is the editable JSON option) | |||

[[File:Send Configuration .png|frameless|620x620px]] | |||

Data sender Configuration is divided into major 2 parts, | |||

'''JSON''' | |||

'''CSV''' | |||

JSON is further divided into 1 category, | |||

'''Modbus Sender:''' | |||

[[File:Modbus Sender.png|frameless|620x620px]] | |||

Select the field input you wish to add from the ‘Field Content tab’. | |||

Give a desired JSON Key Name you wish to publish in the ‘Field JSON Key Name’ tab. | |||

Once configured, click on Add. | |||

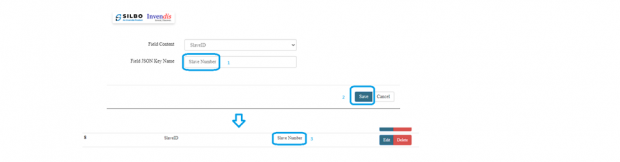

JSON option allows editable JSON in which we can change which parameters should be sent and what name we should use to the tag. | |||

[[File:Modbus Sender a1.png|frameless|620x620px]] | |||

What changes we can do in JSON edit to the above list. | |||

Let’s change slave_id to some other name as “Slave number”. | |||

[[File:Modbus Sender 1.b.png|frameless|620x620px]] | |||

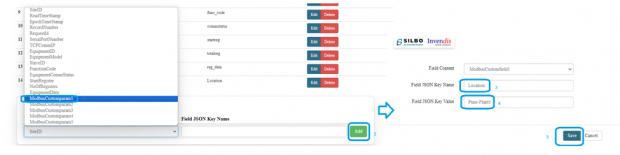

Even custom fields can be added, for example if location name should be sent by router/gateway in JSON packet then it can be configured as shown. | |||

[[File:Modbus Sender 1.c.png|frameless|620x620px]] | |||

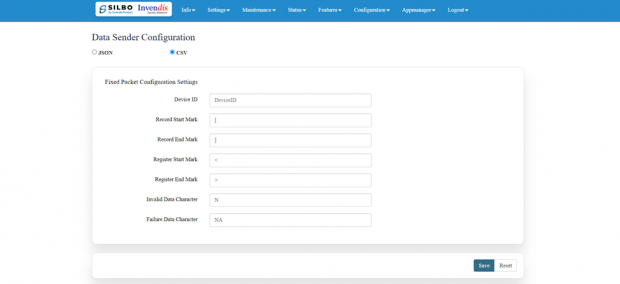

'''CSV:''' | |||

This option sends data packets in CSV (Comma-Separated Values) format. | |||

[[File:CSV Data Packets Sending.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Device ID | |||

|PC312 | |||

|A unique identifier for the device. | |||

|- | |||

|2 | |||

|Record Start Mark | |||

|[ | |||

|This character marks the beginning of a data record. It's used to indicate where a new data record starts in the transmitted packet. | |||

|- | |||

|3 | |||

|Record End Mark | |||

|] | |||

|This character marks the end of a data record. It signals the end of the data for one record before a new one starts. | |||

|- | |||

|4 | |||

|Register Start Mark | |||

|< | |||

|This character marks the beginning of a register within a data record. A register typically represents an individual data field within the record. | |||

|- | |||

|5 | |||

|Register End Mark | |||

|> | |||

|This character marks the end of a register within a data record. It indicates where the data for a particular field end. | |||

|- | |||

|6 | |||

|Invalid Data Character | |||

|N | |||

|Used to indicate that the data for a particular register is invalid or could not be collected. This helps in identifying which data points are not usable. | |||

|- | |||

|7 | |||

|Failure Data Character | |||

|NA | |||

|Used to indicate that there was a failure in collecting or processing the data for a particular register. It signifies that an error occurred, and the data point could not be obtained. | |||

|} | |||

Click on save once changes are made. | |||

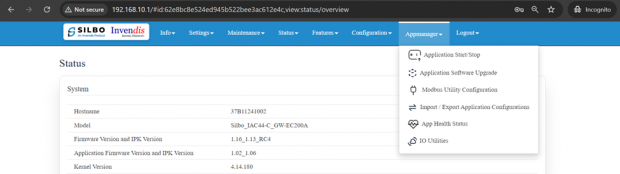

= 7. Appmanager = | |||

'''Appmanager''' is a system utility that manages the installation, configuration, and execution of software applications on a device. | |||

This section is divided into 8 categories, | |||

* Application Start/Stop | |||

* Application Software Upgrade | |||

* Modbus Utility Configuration | |||

* Import/Export Application Configurations | |||

* App Health Status | |||

* IO Utilities | |||

[[File:IAC44C_App_Manager.png|frameless|620x620px]] | |||

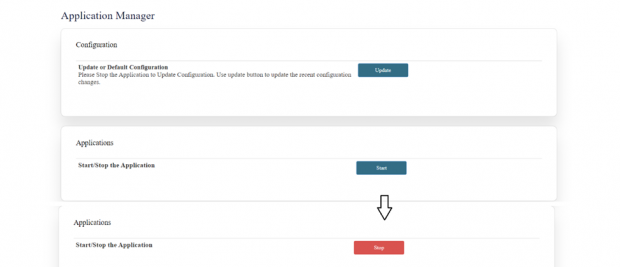

=== 7.1 Application Start/Stop === | |||

All changes made in ‘'''Configuration’''' section should be saved into backend and to do that navigate to Appmanager>> Application Start/Stop. | |||

Click on update to save all the changes made in configuration section. | |||

Once updated click on start. | |||

[[File:Application_Start-Stop_Configuration.png|frameless|620x620px]] | |||

Make sure application is started to send data to cloud, once started it can be seen start option is replaced by Stop as shown above. | |||

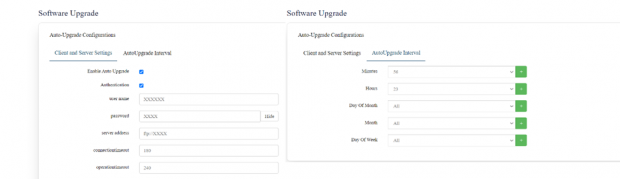

=== 7.2 Application Software Upgrade === | |||

In this section you can upgrade software manually or automatically. | |||

For auto upgrade, enable auto upgrade tab, | |||

This is further divided into 2 sections, | |||

Client and server settings | |||

Auto Upgrade Interval | |||

[[File:Application_Software_Upgrade.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

| colspan="4" |Client and Server Settings | |||

|- | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Authentication | |||

|Enable/Disable | |||

|Enable if username/password is required. | |||

|- | |||

|2 | |||

|Username | |||

|XXXX | |||

|The username required to authenticate with the server. | |||

|- | |||

|3 | |||

|Password | |||

|XXXX | |||

|The password required to authenticate with the server. | |||

|- | |||

|4 | |||

|Server address | |||

|<nowiki>ftp://XXXX</nowiki> | |||

|The URL or IP address of the server where the upgrade files are located. | |||

|- | |||

|5 | |||

|Connection timeout | |||

|Ex: 180 | |||

|The maximum time (in seconds) the system will wait to establish a connection with the server before timing out. | |||

|- | |||

|6 | |||

|Operation timeout | |||

|Ex: 240 | |||

|The maximum time (in seconds) the system will wait for the upgrade operation to complete before timing out. | |||

|- | |||

| colspan="4" |'''Auto Upgrade Interval''' | |||

|- | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Minutes | |||

|Example: 56 | |||

|Set the minute part of the interval when the auto-upgrade check will occur | |||

|- | |||

|2 | |||

|Day Of Month | |||

|Example: all | |||

|Specifies the days of the month when the auto-upgrade check should occur. | |||

|- | |||

|3 | |||

|Month | |||

|Example: all | |||

|Specifies the months during which the auto-upgrade check should occur | |||

|- | |||

|4 | |||

|Day Of Week | |||

|Example: all | |||

|Specifies the days of the week when the auto-upgrade check should occur. | |||

|} | |||

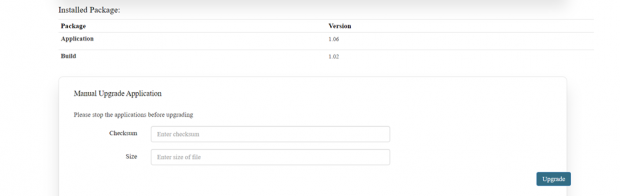

You can also check the current software version and manually upgrade software as shown below. | |||

To Manually upgrade Application, | |||

Enter the correct ‘Checksum’ and ‘Size’ and upgrade the page. | |||

'''(Please stop the applications before upgrading)''' | |||

[[File:Manual_Upgrade_Application.png|frameless|620x620px]] | |||

=== 7.3 Import / Export Gateway Configuration === | |||

This functionality ensures that you can easily manage, back up, and restore device gateway | |||

configurations, as well as reset the device to default settings when needed. | |||

[[File:Import_-_Export_Gateway_Configuration.png|frameless|620x620px]] | |||

'''Export Config:''' | |||

'''Usage:''' Click the "Export Config" button to save the current configuration to a file. | |||

'''Import Config:''' | |||

'''Usage:''' Click the "Import Config" button and select the text file containing the configuration you want to import. | |||

'''Reset Config''': | |||

'''Usage''': Click the "Reset Config" button to revert the device to its default configuration settings. | |||

=== 7.4 App Health Status === | |||

This section provides utilities to check the health and status of various applications and data inputs | |||

within the system. It allows monitoring of the last data produced and sent times for different utilities, as | |||

well as the running status of applications. | |||

[[File:App_Health_Status_2.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|Energymeter Last Data Produced Time | |||

|Command ‘Read’ | |||

|Displays the last time data was produced by the energymeter. | |||

|- | |||

|2 | |||

|DIO Last Data Produced Time | |||

|Command ‘Read’ | |||

|Displays the last time data was produced by the digital input/output system. | |||

|- | |||

|3 | |||

|Energymeter Last Data Sent Time | |||

|Command ‘Read’ | |||

|Displays the last time data from the energymeter was sent. | |||

|- | |||

|4 | |||

|DIO Last Data Sent Time | |||

|Command ‘Read’ | |||

|Displays the last time data from the digital input/output system was sent. | |||

|- | |||

|5 | |||

|App Running Status | |||

|Command ‘Read’ | |||

|Displays the current running status of applications. | |||

|- | |||

|6 | |||

|Download Files | |||

|Command ‘Download’ | |||

|Choose the desired option from the dropdown menu. | |||

Download data or logs related to the options available. | |||

|- | |||

|7 | |||

|Output | |||

|Display Value | |||

|Provides output or feedback based on selected utilities. | |||

|} | |||

=== 7.5 Modbus Utility Configuration === | |||

Any changes to be made in Modbus Configuration to test can be made in Modbus Utility Configuration without disturbing the actual Modbus Configuration. | |||

The working process of ‘Modbus Configuration’ and ‘Modbus Utility Configuration’ are same. | |||

Refer (6.5 Modbus Configuration) for specification details. | |||

[[File:Modbus_Utility_Configuration.png|frameless|620x620px]] | |||

Click on save once configuration changes have been made. | |||

=== 7.6 IO Utilities === | |||

This section provides output of various utilities connected to the device. | |||

This section exactly shows whether the connection made is successful or not. | |||

[[File:IO_Utilities_2.png|frameless|620x620px]] | |||

Specification details are given below: | |||

{| class="wikitable" | |||

|SN | |||

|Field Name | |||

|Sample Value | |||

|Description | |||

|- | |||

|1 | |||

|RS485 EnergyMeter | |||

|'''Input''': Slave ID | |||

|'''Action''': Manage RS485 energy meters by specifying the slave ID. | |||

|- | |||

|4 | |||

|Digital Input (DIO) | |||

|'''Input''': Select from 1, 2, 3, 4 | |||

|'''Action''': Manage digital input settings. | |||

|- | |||

|5 | |||

|Digital Output (DO) | |||

|'''Input''': Select from 1, 2, 3, 4 and specify the value (0 or 1) | |||

|'''Action''': Manage digital output settings. | |||

|- | |||

|7 | |||

|Output | |||

|Print any values | |||

|'''Action''': Will display the results or status messages based on the actions performed using the utilities. | |||

|} | |||

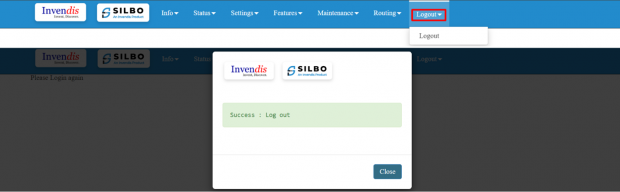

= 8.Logout = | |||

The user should click on log out option to logged out from the router application. | |||

[[File:Logout.png|frameless|620x620px]] | |||

Revision as of 09:19, 20 August 2024

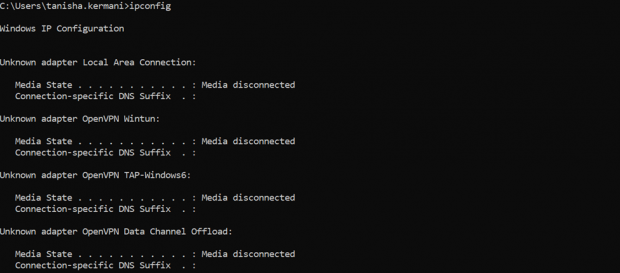

Connecting with Protocol Converter to the System (Laptop/Desktop)

To log in to SILBO_PC312 by connecting the Protocol converter to your laptop or desktop via LAN or using Wi-Fi, please follow the steps below.

Connecting via LAN:

Connect your laptop's LAN port to the Protocol Converter’s LAN interface.

How to connect with the SILBO_PC312 application

Once the LAN connection is established between the device and the laptop or the desktop

Please open the command prompt and ping to get the IP config of that device.

Type the command Ipconfig

It will provide the Ip address/url of that device through which the application can be accessed.

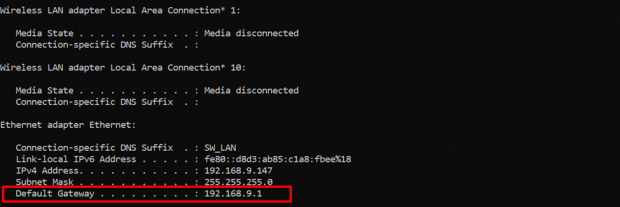

Log In

Open the web browser and type the IP address in the URL.

It will show the log in page of the application.

Give the valid credentials for the username and password to login to the application page.

Once the user credentials are provided it will direct to the landing page of the application.

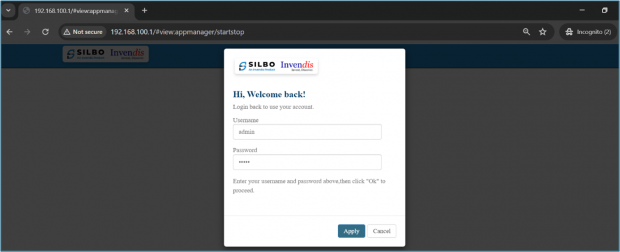

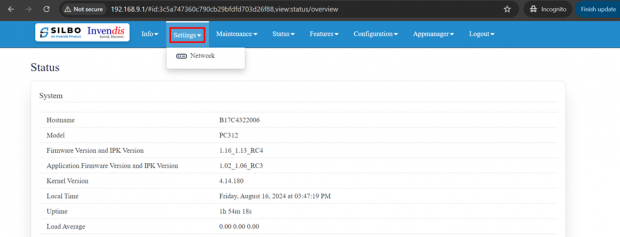

The “Status” landing page shows all the detailed specification of the device like system, memory storage and connection tracking etc.

The application is divided in to 8 Modules.

- Info

- Settings

- Maintenance

- Status

- Features

- Configuration

- Appmanager

- Logout

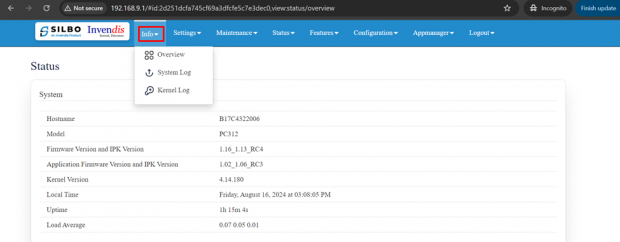

1. Info

The “Info” module provides the information about the devices to the user.

It provides all the specification related to the hardware, firmware, Networks and the Connection uptimes.

It has 3 submodules.

- Overview

- System Log

- Kernel Log

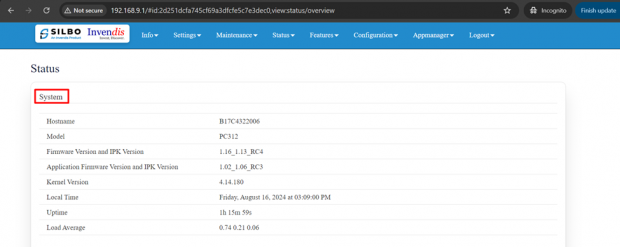

1.1 Overview

In overview module it displays all the specification categorically of a device like System, Memory, storage, Connection tracking, DHCP Lease.

System:

In this section it displays the hardware configured specification of the device.

The specifications details are as follows,

| SN | Field name | Sample value | Description |

| 1 | Hostname | B17C4322006 | This field displays the router serial number of the device |

| 2 | Model |

|

This field displays the model number of the device |

| 3 | Firmware Version and IPK Version | 1.16_1.13_RC4 | This field displays the firmware version and IPK version |

| 4 | Application Firmware version and IPK version |

|

This field displays the software version of the device. |

| 5 | Kernel Version | 4.14.180 | This field displays the kernel version of the device |

| 6 | Local Time | Tuesday, August 6, 2024 at 01:15:07 PM | This field displays the local time |

| 7 | Uptime | 1d 2h 23m 25s | This field displays the uptime of the device |

| 8 | Load Average | 0.45 0.30 0.19 | This field displays the average load |

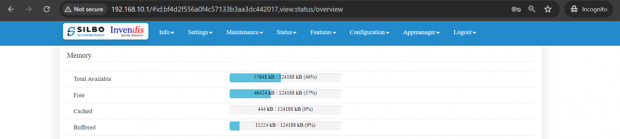

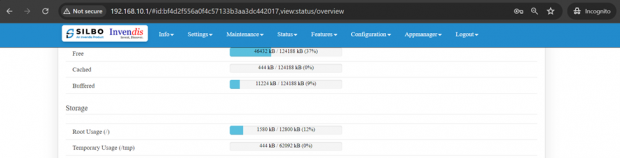

Memory: In this section it displays the memory configured specification of the device.

The specifications details are as follows.

| SN | Field name | Sample value | Description |

| 1 | Total Available | 57716 kB / 124188 kB (46%) | This field displays the total availability of memory space in the device |

| 2 | Free | 46424 kB / 124188 kB (37%) | This field displays the Free memory space in the device |

| 3 | Cached | 444 kB / 124188 kB (0%) | This field displays the Cached memory space in the device |

| 4 | Buffered | 11224 kB / 124188 kB (9%) | This field displays the Buffered memory space in the device |

Storage: In this section it displays the status of storage as root and temporary usage specification of the device.

The specifications details are as follows.

| SN | Field name | Sample value | Description |

| 1 | Root Usage | 1580 kB / 12800 kB (12%) | This field displays the total root usage of the device |

| 2 | Temporary Usage | 444 kB / 62092 kB (0%) | This field displays the total temporary usage of the device |

Connection Tracking:

In this section it displays the status of connection tracking for the device.

The specifications details are as follows.

| SN | Field Value | Sample Value | Description |

| 1 | Active Connections | 48/16384 (0%) | This field displays the active connection of the device. |

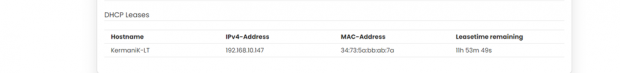

DHCP Leases:

In this section it displays the DHCP lease of the temporary assignment of an IP address to a device on the network.

The specifications details are below.

| SN | Field name | Sample value | Description |

| 1 | Host Name | KermaniK-LT | This field displays the configured Host Name/Username for that device. |

| 2 | IPv4-Address | 192.168.10.147 | This field displays the IP address of the device. |

| 3 | MAC-Address | 34:73:5a:bb: ab:7a | This field displays the MAC-Address of the device. |

| 4 | Lease time remaining | 11h 53m 49s | This field displays the lease time remaining for the device. |

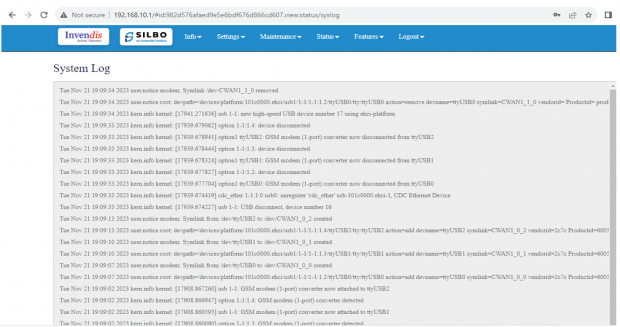

1.2 System Log

This page provides on screen System logging information. In this page the user gets to view the system logs.

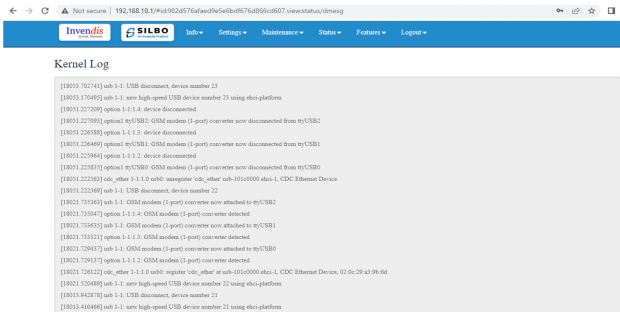

1.3 Kernel Log

This page provides on screen Kernel logging information.

In this page the user gets to view the Kernel logs.

2. Setting

In this “Setting” module the user can Configure/update all the required parameters related to Network and Wifi settings as per requirement.

IT consist of 1 submodule.

- Network

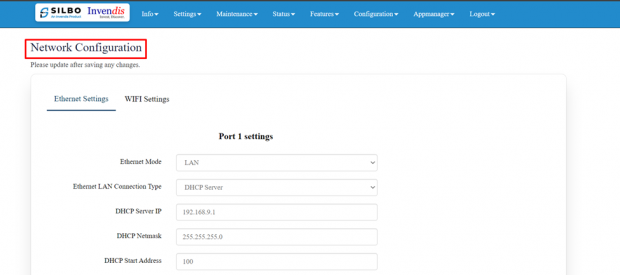

2.1 Network

In this section the user does all the setting related configuration with reference to network like Ethernet Settings and Wi-Fi Settings.

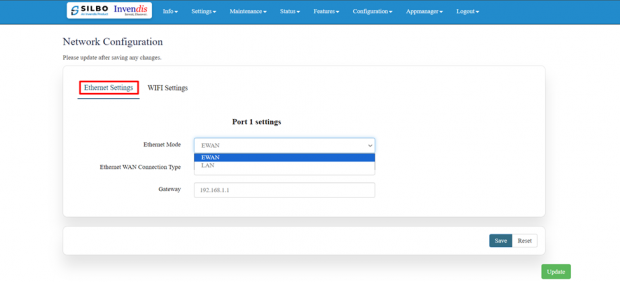

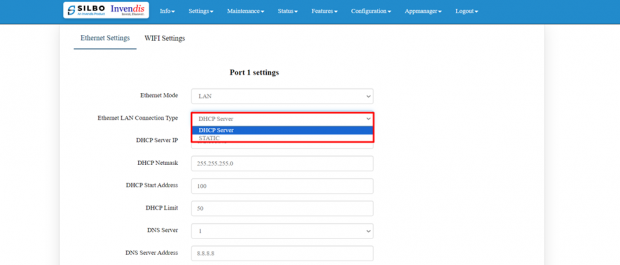

Ethernet Setting:

In this page it will display the configured port that is attached with the device.

For this device 1 port is configured.

Ethernet LAN Connection settings can be configured as DHCP server or Static.

For port 1 setting,

Kindly select the option LAN for Port 1 mode LAN/WAN. Based on the option selected the field will also change. The user needs to configure all the required field and click on save.

Specification details are given below:

| SN | Field name | Sample value | Description |

| 1 | Ethernet Mode | LAN | This field displays the port mode selection |

| 2 | Port 1 Ethernet Protocol [LAN Eth0.1] | 1.) DHCP Server

2.) Static |

This field displays the Ethernet mode selection |

| 3 | Port 1 DHCP Server IP

Port 1 Static IP |

1.) 192.168.9.1

2.) 192.168.9.1 |

This field displays DHCP server and static IP configured. |

| 4 | Port 1 DHCP and Static Netmask | 255.255.255.0 | This field displays DHCP server and static Netmask address configured |

| 5 | Port 1 DHCP Start Address | 100 | This field displays DHCP server start address configured |

| 6 | Port 1 DHCP Limit | 50 | This field displays DHCP server limit |

| 7 | DNS Server | Options: 1,2 | Select the number of DNS Server to configure (max 2). |

| 8 | DNS server address | Ex: 8.8.8.8 | Enter the DNS server IP address upon selection. |

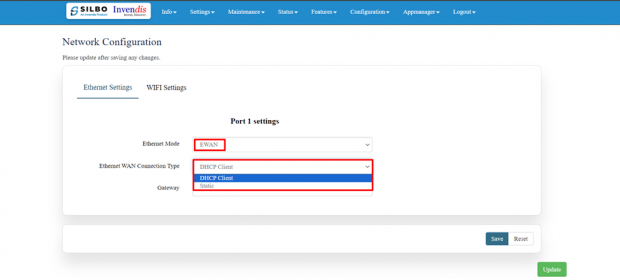

Kindly select the option EWAN for Port 1 mode LAN/WAN. Based on the option selected the field will also change. The user needs to configure all the required field and click on the save to save the required fields.

The specifications details are below.

| SN | Field name | Sample value | Description |

| 1 | Ethernet Mode | EWAN | This field displays the port mode selection |

| 2

|

Ethernet Protocol Port 1 WAN | 1.) DHCP client

2.) Static |

1.) Automatically obtains IP address and network configuration from a DHCP server.

2.) Manually set a fixed IP address and network configuration. |

| 3 | Gateway | 192.168.1.1 | This field displays gateway address configured |

Click on the save once all the configuration is done and click on the update button to update all the information.

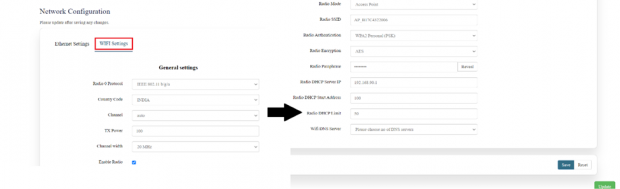

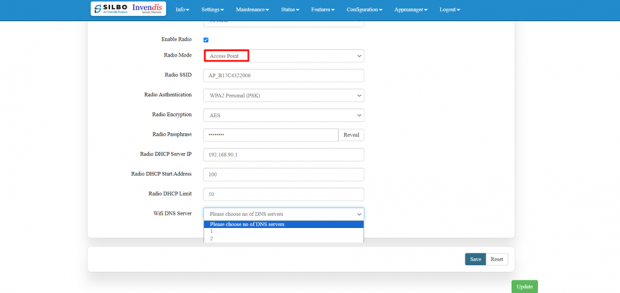

Wi-Fi Setting:

In this, router has the general setting and change country code, channel, radio mode, radio passphrase as per the requirement after clicking on enable Radio button.

It has 1 radio mode,

Access point

Access Point mode:

In Access Point mode, a configuration in which a router, allows wireless devices to connect to a wired network by creating a Wi-Fi hotspot.

The specifications details are below.

| SN | Field name | Sample value | Description |

| 1 | Radio 0 Protocol | IEEE 802.11 b/g/n | This section shows the radio protocol which is by default. |

| 2 | Country Code | INDIA | Select the country accordingly.

(INDIA by default) |

| 3 | Channel | Auto | In this dropdown the user should select the proper channel to be used. (Auto by default) |

| 4 | TX Power | 100 | In this text box the user should specify the power. |

| 5 | Channel Width | 20 MHz | In this dropdown the user should select the channel width |

| 6 | Radio Mode | 1.) Access point | In this drop down the user should select the mode.

(Access point by default) |

| 7 | Radio SSID | AP_37A26230014 | In this text box the user should specify the SSID number which usually comes with the router. |

| 8 | Radio Authentication | WPA2 Personal (PSK) | In this dropdown the user should select the type of authentication.

(WPA2 Personal (PSK) by default) |

| 9 | Radio Encryption | AES | In this dropdown the user should select the type of encryption required.

(AES by default) |

| 10 | Radio Passphrase | ********* | In this text box the user should specify the password. Password will be given with the router which can be changed later. |

| 11 | Radio DHCP server IP | 192.168.100.1 | In this text box the user should specify the IP address of DHCP server.

(192.168.100.1 will be default which can be changed accordingly) |

| 12 | Radio DHCP start address | 100 | In this text box the user should specify the start address of the DHCP.

(100 value is default) |

| 13 | Radio DHCP limit | 50 | In this text box the user should specify the limit for the DHCP.

(50 value is default) |

| 14 | DNS Server | Options: 1,2 | Select the number of DNS Server to configure (max 2). |

| 15 | DNS server address | Ex: 8.8.8.8 | Enter the DNS server IP address upon selection. |

Click on save once changes have been made.

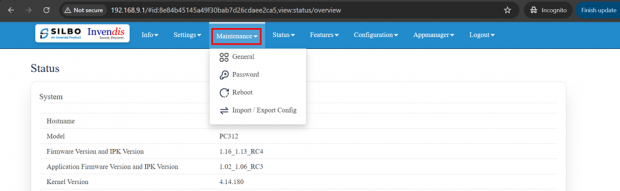

3.Maintenance

In this module the user can configure/upgrade/modify the settings related to system, password,

firmware and monitoring.

It includes 4 submodules.

- General

- Password

- Reboot

- Import and Export config

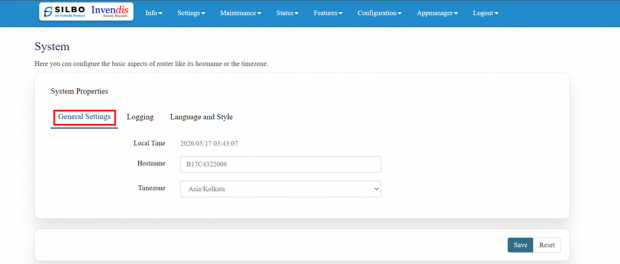

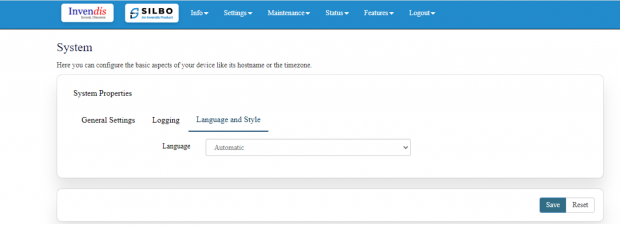

3.1 General

Here you can configure the basic aspects of the Protocol Convertor like its hostname or the time zone.

It is further sub-divided into,

1.) General Settings

2.) Logging

3.) Language and Style

General Settings:

EDIT:

| SN | Field Name | Sample Value | Description |

| 1 | Local Time | 2024/07/30 13:25:47 | The current local date and time set on the device. |

| 2 | Hostname | B17C4322006 | The hostname of the device, which is used to identify it on the network. |

| 3 | Timezone | Asia/Kolkata | The timezone setting of the device, which determines the local time. |

Once the user configures the required details then click on the save button to save all the details.

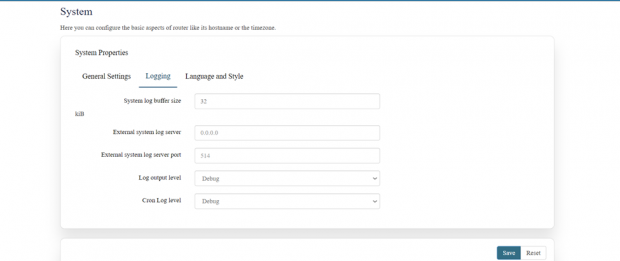

Logging:

Here the user can configure the basic aspects of your device related to system.

The system log configuration provided specifies how the device handles and stores log information, including buffer size, external log server details, and log verbosity levels.

EDIT:

| SN | Field Name | Sample Value | Description |

| 1 | System log buffer size | Example: 32 kiB | The size of the memory buffer allocated (0-32) for storing system logs before they are either written to a file or sent to an external server. |

| 2 | External system log server | Example: 0.0.0.0 | The IP address of an external server where logs can be sent. |

| 3 | External system log server port | Example: 514 | The port used to send logs to the external log server. Port 514 is the default port for syslog. |

| 4 | Log output level | Example: Debug | Sets the detail level of the system logs. |

| 5 | Cron Log level | Example: Debug | The detail level of the logs for cron jobs. |

Once the user configures the required details then click on the save button to save all the details.

Language and Style:

Here the user can configure the basic aspects of your device related to language.

Once the user configures the required details then click on the save button to save all the details.

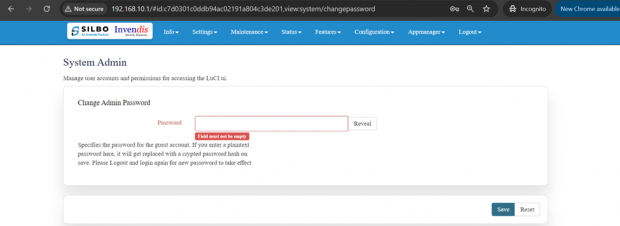

3.2 Password

In this module the user can set the password for the admin credentials.

Specifies the password for the guest account. If the user enters a plaintext password here, it will get replaced with a crypted password on save. The new password will be effective once the user logs out and log in again.

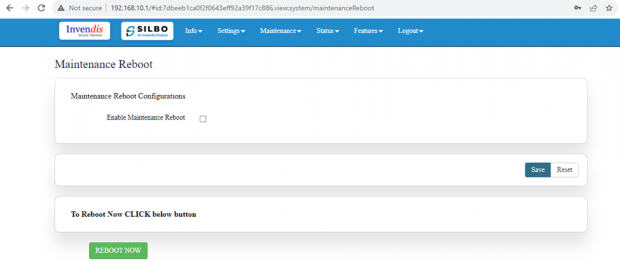

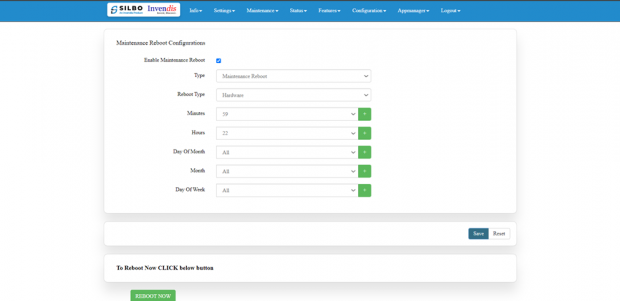

3.3 Reboot

In this module the user can reboot the device remotely.

First option is to directly reboot the device without enabling the maintenance reboot tab.

Click on “Reboot Now” at the bottom of the screen to start the reboot process.

To start maintenance reboot process first the user needs to fill all the required fields.

Need to select the type of reboot for the device whether it needs to be Hardware or Software reboot.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Enable Maintenance Reboot | Enable/Disable | Indicates whether the maintenance reboot feature is enabled or not. |

| 2 | Type | Maintenance Reboot | Specifies the type of reboot being scheduled. |

| 3 | Reboot Type | Software/Hardware | Hardware: A hardware reboot involves restarting the entire device as if it were powered off and on again.

Software: A software reboot involves restarting the operating system without powering off the hardware. |

| 4 | Minutes | Example: 59 | The minute at which the reboot should occur (0-59). |

| 5 | Hours | Example: 22 (10 PM) | The hour at which the reboot should occur (0-23, in 24-hour format). |

| 6 | Day Of Month | Example: All | Specifies which days of the month the reboot should occur (1-31). "All" means it will occur every day. |

| 7 | Month | Example: All | Specifies which months the reboot should occur (1-12). "All" means it will occur every month. |

| 8 | Day Of Week | Example: All | Specifies which days of the week the reboot should occur (0-6, where 0 is Sunday). "All" means it will occur every day of the week. |

Once the user fills all the required given parameters click on the save.

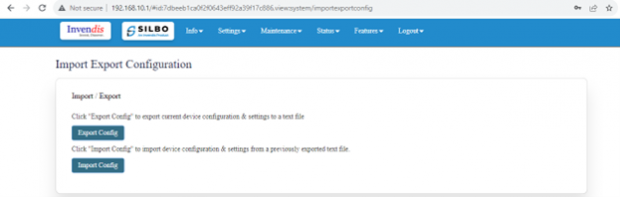

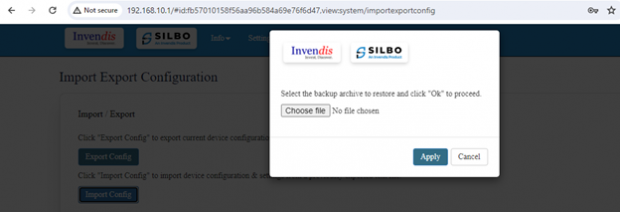

3.4 Import and Export

In this section, User can Import & Export Configuration files of the Device.

Click “Export Config” to export device configuration & settings to a text file,

Click “Import Config” to import device configuration & settings from a previously exported text file.

The user needs to select on the “choose file”, upload the required file and click on apply.

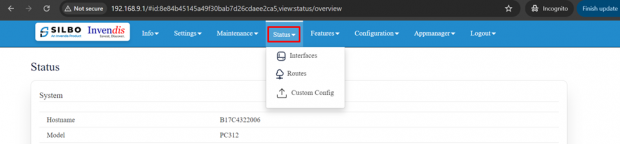

4.Status

In this module the user can view the status of the router device with respect to the network, Wan, modem etc.

It has 3 submodules.

- Interfaces

- Routes

- Custom Config

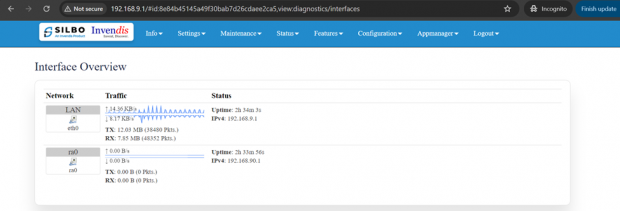

4.1 Interfaces

Each network device (interface) is associated with specific traffic statistics, uptime, and status. Active interfaces are operational.

Looking on the network status the user can check if the ewan is up.

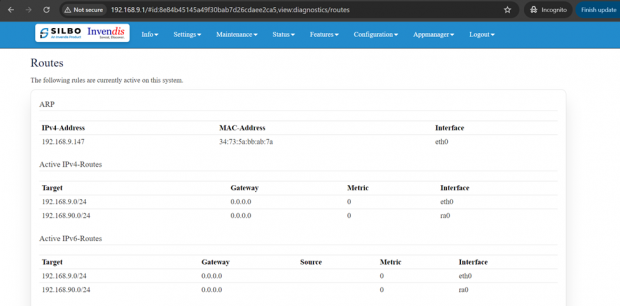

4.2 Routes

This configuration shows how the router directs traffic between different networks and interfaces, ensuring proper communication within the local network and to external networks via the default gateway.

ARP Table: Maps IP addresses to MAC addresses for devices on the network, helping in identifying which device is on which interface.

IPv4 Routes: This shows which network is directly connected on which interface.

Example: Network 192.168.9.0/24 is directly connected on interface eth0.1.

IPv6 Routes: Similar routes as IPv4, but this time listed under IPv6 routing rules.

Example: Local networks 192.168.9.0/24 and 192.168.90.0/24 are managed through eth0.1 and ra0, respectively.

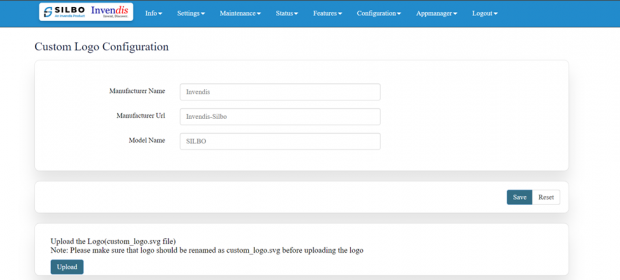

4.3 Custom Config

In this section, webpage logo can be customised as per requirements.

Upload the custom logo by clicking the “Upload” tab below.

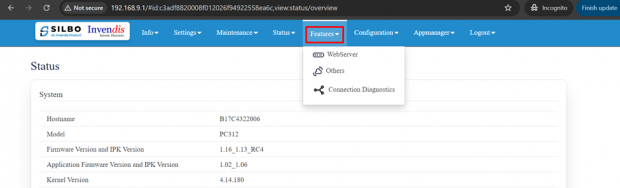

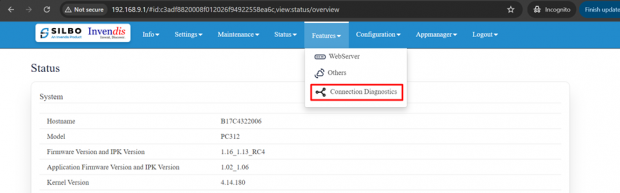

5. Features

In this module the user can see all the features that the router device has.

This module includes 3 features.

- Web Server

- Others

- Connection Diagnostics

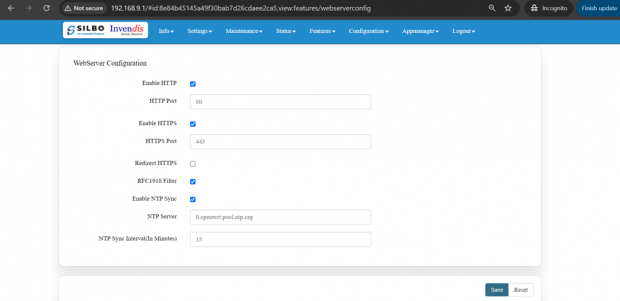

5.1 Web Server

This configuration will allow your device to serve web traffic securely over HTTPS, keep its system time synchronized, and ensure that all HTTP traffic is redirected to HTTPS for better security.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Enable HTTP | HTTP Port: 80

Enable or disable the HTTP server. |

Port 80 is the default port for HTTP traffic. It is used to serve web pages over an unencrypted connection. |

| 2 | Enable HTTPS | HTTPS Port: 443

Enable or disable the HTTPS server. |

Port 443 is the default port for HTTPS traffic. It is used to serve web pages over an encrypted connection. |

| 3 | Redirect HTTPS | Option to redirect HTTP traffic to HTTPS. | When enabled, all HTTP requests will be automatically redirected to the HTTPS port to ensure secure communication. |

| 4 | Enable NTP Sync | Enable or disable NTP synchronization. | Synchronizes the device’s system clock with an external NTP server to maintain accurate time. |

| 5 | NTP Server | 0.openwrt.pool.ntp.org | The address of the NTP server used for time synchronization. The openwrt.pool.ntp.org server is a public NTP server pool. |

| 6 | NTP Sync Interval (In Minutes) | 15 | The interval at which the device will sync its clock with the NTP server, set to every 15 minutes in this case. |

Click on save once changes are made.

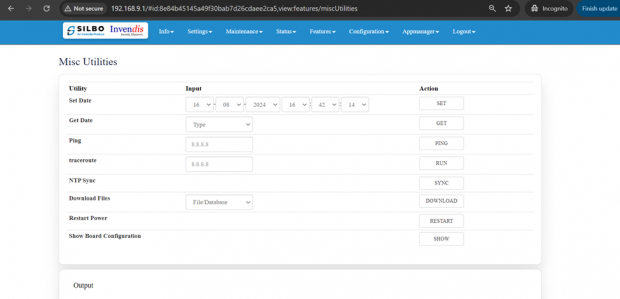

5.2 Others

In this page the user will get to do all the other miscellaneous configuration with respect to the device based on the required parameters. Each utility serves a specific purpose, providing various functionalities for managing and troubleshooting network configurations and statuses.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Set Date | Date and time fields (day, month, year, hour, minute, second) | Sets the system date and time to the specified values. |

| 2 | Get Date | System | Retrieves and displays the current system date and time. |

| 3 | Ping | IP address or domain (e.g., 8.8.8.8) | Sends ICMP echo requests to the specified address to check connectivity. |

| 4 | traceroute | IP address or domain (e.g., 8.8.8.8) | Traces the route packets take to reach the specified address. |

| 5 | NTP Sync | Command ‘Sync’ | Synchronizes the system time with the configured NTP server. |

| 6 | Download Files | File or database identifier | Initiates a download of the specified file or database. |

| 7 | Restart Power | Command ‘Restart’ | Restarts the power of the device. |

| 8 | Show Board Configuration | Command ‘Show’ | Displays the current board configuration. |

| 9 | Output | Any value | Displays output for all the above actions. |

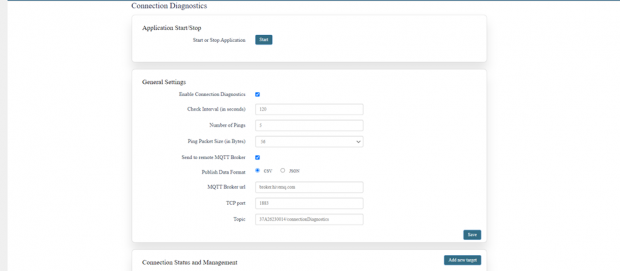

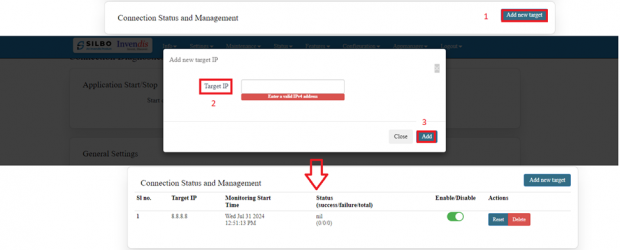

5.3 Connection Diagnostics

This can ensure that your connection diagnostics application effectively monitors and reports the status of your network connections, providing valuable data for troubleshooting and performance optimization.

This Application works in 3 parts,

1.) General settings

2.) Connection status and management

3.) Application Start/Stop

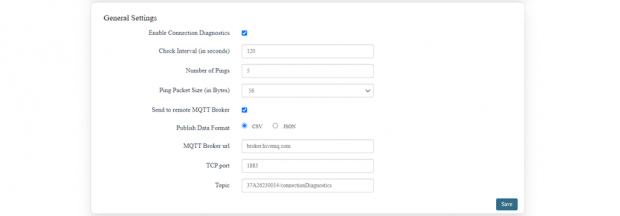

General settings:

First make configuration changes in this section and save.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Enable Connection Diagnostics | Enable/Disable | This option enables or disables the connection diagnostics functionality. |

| 2 | Check Interval (in seconds) | Value: 120 | Specifies how often (in seconds) the diagnostics checks are performed. In this case, every 120 seconds. (min 60 secs) |

| 3 | Number of Pings | Value: 5 | Determines ping requests sent during each check. |

| 4 | Ping Packet Size (in Bytes) | Value: 56 | Defines the size of each ping packet in bytes. |

| 5 | Send to remote MQTT Broker | Enable/Disable | This option enables the sending of diagnostic data to a remote MQTT broker. |

| 6 | Publish Data Format | CSV / JSON | Specifies the format in which the diagnostic data will be published to the MQTT broker. You can choose either CSV (Comma-Separated Values) or JSON (JavaScript Object Notation). |

| 7 | MQTT Broker url | Value: broker.hivemq.com | The URL of the MQTT broker where the diagnostic data will be sent. |

| 8 | TCP port | Value: 1883 | The TCP port used to connect to the MQTT broker. Port 1883 is the default port for MQTT. |

| 9 | Topic | Value: 37A26230014/connectionDiagnostics | The MQTT topic under which the diagnostic data will be published. This topic is used to categorize and identify the data. |

Connection status and management:

To setup a connection,

Click on ‘Add new target’

Enter Target IP (Ex: 8.8.8.8)

Click ‘Add’

Target has been added successfully.

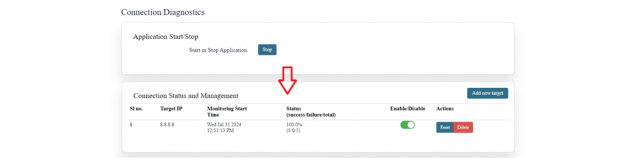

Application Start/Stop:

To check whether the target Ip is sending and receiving packets, you need to start the application to see the desired output.

As shown above, our target Ip is sending packets successfully.

You can Add as many targets IP’s you need to monitor.

You can leave the application on for monitoring else ‘Stop’ the application.

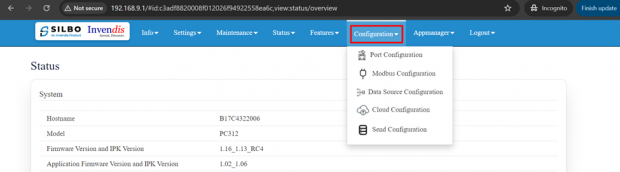

6.Configuration

These are gateway features that can be configured as per requirements.

It is divided into 5 sections,

1.) Port Configuration

2.) Modbus Configuration

3.) Data Source Configuration

4.) Cloud Configuration

5.) Send Configuration

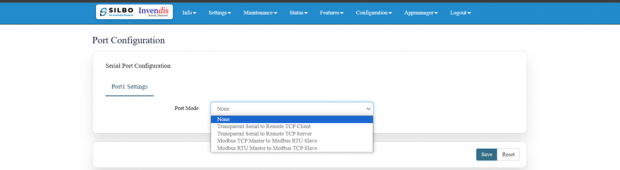

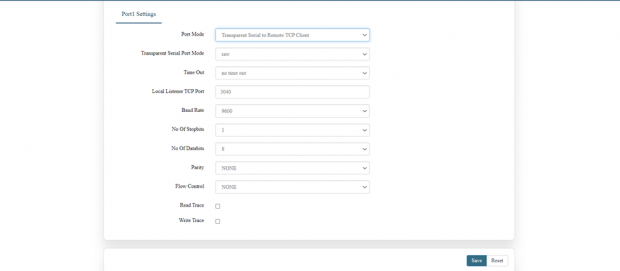

6.1 Port Configuration

Serial port configuration involves setting parameters for serial communication, allowing data exchange between devices via serial ports.

Port Configuration is divided into 4 port mode,

Transparent Serial to Remote TCP Client

Transparent Serial to Remote TCP Server

Modbus TCP Master to Modbus RTU Slave

Modbus RTU Master to Modbus TCP Slave

Transparent Serial to Remote TCP Client:

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Port Mode | Transparent Serial to Remote TCP Client | Configures the serial port to send data directly to a remote TCP client without any additional protocol layers, making it "transparent." |

| 2 | Transparent Serial Port Mode | 1.) raw

2.) rawlp 3.) telnet 4.) off |

1.) It's a straightforward data transfer where the serial data is sent as-is.

2.) "Rawlp" stands for "raw with local processing". Typically, it involves some minimal local processing before transmission. 3.) This allows the serial connection to be accessed and managed over a Telnet session. 4.) The "off" mode disables the transparent serial port functionality. |

| 3 | Time Out | no time out | Ensures that the serial port does not time out, meaning it will continuously wait for data without closing the connection due to inactivity. |

| 4 | Local Listener TCP Port | 3040 | Sets the TCP port number to 3040 for the local listener to accept incoming TCP connections. |

| 5 | Baud Rate | 9600 | This is a common baud rate for serial communication, balancing speed and reliability. |

| 6 | No Of Stopbits | 1 | Configures the serial communication to use 1 stop bit, which is a common setting ensuring the end of each byte is clearly marked. |

| 7 | No Of Databits | 8 | Sets the number of bits in each transmitted byte to 8. |

| 8 | Parity | 1.) None

2.) Even 3.) Odd 4.) Space 5.) Mark |

1.) No parity bit is added to the data byte.

2.) Ensures that the total number of 1-bits in the data byte plus the parity bit is even. 3.) Ensures that the total number of 1-bits in the data byte plus the parity bit is odd. 4.) The parity bit is always set to 0, regardless of the data. 5.) The parity bit is always set to 1, regardless of the data. |

| 9 | Flow Control | 1.) RTSCTS

2.) NONE 3.) DTRDSR 4.) XONXOFF |

1.) Request to Send / Clear to Send

2.) No flow control is used. 3.) Data Terminal Ready / Data Set Ready 4.) Software flow control using specific control characters (XON and XOFF) to manage data flow. |

| 10 | Read Trace | Enable/Disable | Enables logging of data being read from the serial port. |

| 11 | Write Trace | Enable/Disable | Enables logging of data being written to the serial port. |

Click on save once configuration changes are made.

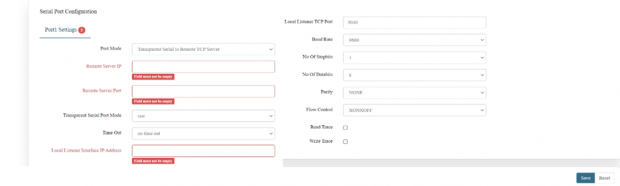

Transparent Serial to Remote TCP Server:

Configures the port to act as a bridge, converting serial data into TCP packets sent to a remote TCP server.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Port Mode | Transparent Serial to Remote TCP Server | Defines how the serial port will operate in relation to the remote server. |

| 2 | Remote Server IP | Ex: 192.168.10.1 | Field must not be empty: This is a required field, and you must provide a valid IP address for proper communication. |

| 3 | Remote Server Port | Ex: 1883 | Field must not be empty: This is a required field, and you must specify the correct port number used by the server. |

| 4 | Transparent Serial Port Mode | 1.) raw

2.) rawlp 3.) telnet 4.) off |

1.) It's a straightforward data transfer where the serial data is sent as-is.

2.) "Rawlp" stands for "raw with local processing". Typically, it involves some minimal local processing before transmission. 3.) This allows the serial connection to be accessed and managed over a Telnet session. 4.) The "off" mode disables the transparent serial port functionality. |

| 5 | Time Out | no time out | Ensures that the serial port does not time out, meaning it will continuously wait for data without closing the connection due to inactivity. |

| 6 | Local Listener Interface IP Address | Field must not be empty: This is a required field for specifying which local IP address will be used for listening. | |

| 7 | Local Listener TCP Port | 3040 | The TCP port number on the local device that will be used to listen for incoming data. |

| 8 | Baud Rate | 9600 | Standard baud rate, common for many serial devices. |

| 9 | No Of Stopbits | 1 | Indicates that one stop bit is used, which is standard for most serial communications. |

| 10 | No Of Databits | 8 | Indicates that 8 data bits are used per byte, which is a common setting. |

| 11 | Parity | 1.) None

2.) Even 3.) Odd 4.) Space 5.) Mark |

1.) No parity bit is added to the data byte.

2.) Ensures that the total number of 1-bits in the data byte plus the parity bit is even. 3.) Ensures that the total number of 1-bits in the data byte plus the parity bit is odd. 4.) The parity bit is always set to 0, regardless of the data. 5.) The parity bit is always set to 1, regardless of the data. |

| 12 | Flow Control | 1.) RTSCTS

2.) NONE 3.) DTRDSR 4.) XONXOFF |

1.) Request to Send / Clear to Send

2.) No flow control is used. 3.) Data Terminal Ready / Data Set Ready 4.) Software flow control using specific control characters (XON and XOFF) to manage data flow. |

| 13 | Read Trace | Enable/Disable | Option to enable tracing of incoming data from the serial port, useful for debugging. |

| 14 | Write Trace | Enable/Disable | Option to enable tracing of outgoing data from the serial port, useful for debugging. |

Click on save once configuration changes are made.

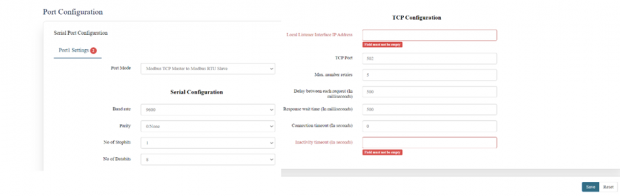

Modbus TCP Master to Modbus RTU Slave:

Configures the serial port to function as a Modbus TCP Master that communicates with a Modbus RTU Slave over the serial connection.

This setup is used to send Modbus TCP commands to a Modbus RTU device via a serial-to-TCP gateway.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Port Mode | Modbus TCP Master to Modbus RTU Slave | This setup is used to send Modbus TCP commands to a Modbus RTU device via a serial-to-TCP gateway. |

| 2 | Baud Rate | 9600 | The speed at which data is transmitted over the serial connection. |

| 3 | Parity | 1.) None

2.) Even 3.) Odd |

1.) No parity bit is used, meaning no additional error-checking bits are included.

2.) Ensures that the total number of 1-bits in the data byte plus the parity bit is even. 3.) Ensures that the total number of 1-bits in the data byte plus the parity bit is odd. |

| 4 | No of Stopbits | 1 | Indicates that one stop bit is used, which is standard for most serial communications. |

| 5 | No of Databits | 8 | Indicates that 8 data bits are used per byte, which is a common setting. |

| 6 | Local Listener Interface IP Address | Field must not be empty: You need to provide a valid IP address where the TCP connections will be received. | |

| 7 | TCP Port | 502 | This is the standard port for Modbus TCP communication. |

| 8 | Max. Number of Retries | 5 | The maximum number of times to retry sending a request if the initial attempt fails. |

| 9 | Delay Between Each Request (In milliseconds) | 500 | The delay between consecutive Modbus requests to avoid overwhelming the system or device. |

| 10 | Response Wait Time (In milliseconds) | 500 | The maximum time to wait for a response from the Modbus RTU Slave before considering the request failed. |

| 11 | Connection Timeout (In seconds) | 0 | A value of 0 typically means no timeout is set, so the system will wait indefinitely. |

| 12 | Inactivity Timeout (In seconds) | The time to wait before closing a connection if no activity is detected. |

Click on save once configuration changes have been made.

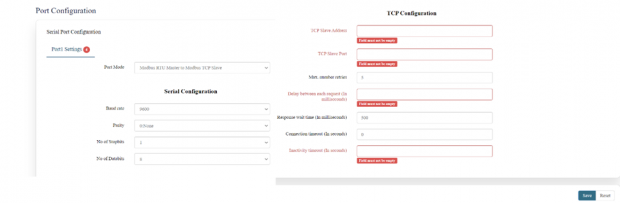

Modbus RTU Master to Modbus TCP Slave:

Configures the serial port to function as a Modbus RTU Master that communicates with a Modbus TCP Slave over a network. This setup is used to send Modbus RTU commands from a master device to a Modbus TCP device via a TCP-to-serial gateway.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Port Mode | Modbus RTU Master to Modbus TCP Slave | This setup is used to send Modbus RTU commands from a master device to a Modbus TCP device via a TCP-to-serial gateway. |

| 2 | Baud Rate | 9600 | The speed at which data is transmitted over the serial connection. |

| 3 | Parity | 1.) None

2.) Even 3.) Odd |

1.) No parity bit is used, meaning no additional error-checking bits are included.

2.) Ensures that the total number of 1-bits in the data byte plus the parity bit is even. 3.) Ensures that the total number of 1-bits in the data byte plus the parity bit is odd. |

| 4 | No of Stopbits | 1 | Indicates that one stop bit is used, which is standard for most serial communications. |

| 5 | No of Databits | 8 | Indicates that 8 data bits are used per byte, which is a common setting. |

| 6 | TCP Slave Address | Field must not be empty | The IP address of the Modbus TCP Slave device to which the master will send requests. |

| 7 | TCP Slave Port | Field must not be empty | The port number on the Modbus TCP Slave device for receiving Modbus requests. |

| 8 | Max. Number of Retries | 5 | The maximum number of times to retry sending a request if the initial attempt fails. |

| 9 | Delay Between Each Request (In milliseconds) | Field must not be empty | The delay between consecutive Modbus requests to avoid overwhelming the system. |

| 10 | Response Wait Time (In milliseconds) | 500 | The maximum time to wait for a response from the Modbus TCP Slave before considering the request failed. |

| 11 | Connection Timeout (In seconds) | 0 | A value of 0 typically means no timeout is set, so the system will wait indefinitely. |

| 12 | Inactivity Timeout (In seconds) | Field must not be empty | The time to wait before closing a connection if no activity is detected. |

Click on save once configuration changes have been made.

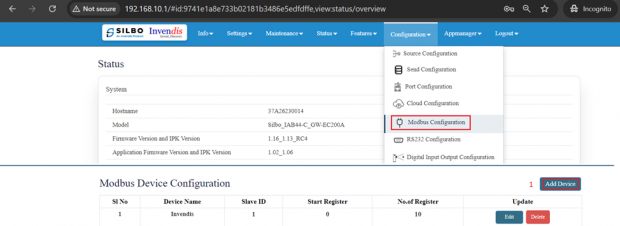

6.2 Modbus Configuration

Modbus Configuration involves setting up communication parameters for Modbus devices, including baud rate, parity, stop bits, data bits, TCP/RTU settings, and timeout/retry settings for reliable data exchange.

Click on “Add Device” to start a new configuration.

This Configuration has 2 sections,

1.) Parameter Configuration

2.) Register Config

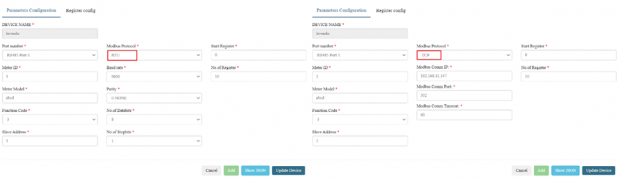

Parameter Configuration:

As shown in the image below, there are two types of protocol used in Modbus configuration.

1.) RTU (Remote Terminal Unit)

2.) TCP (Transmission Control Protocol)

Details of both protocols is mentioned in the specification table.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | DEVICE NAME | Ex: Invendis | This is the name assigned to the Modbus device for identification purposes. |

| 2 | Port number | RS485 Port-1 | This specifies which RS485 port on the device is being used for communication. |

| 3 | Meter ID | 1 | The Meter ID is a unique identifier for the specific meter within the network. Each Modbus device on the network must have a unique ID to differentiate it from others. |

| 4 | Meter Model | Example: abcd | This field specifies the model of the meter. |

| 5 | Function Code | read coils (1)

read input coils (2) read holding registers (3) read input registers (4) |

The function code indicates the operation to be performed. In Modbus, each operation has a specific function code. |

| 6 | Slave Address | Example: 1 | The slave address identifies the specific slave device on the Modbus network. Each slave must have a unique address so that the master can communicate with it individually. |

| Modbus protocol: RTU | |||

| 7 | Baud rate | 300 | 1200 | 1800 | 2400 | 4800 | 19200 | 38400 | default: 9600 | The baud rate determines the communication speed between devices, measured in bits per second. |

| 8 | Parity | 1.) NONE

2.) ODD 3.) EVEN |

1.) No parity bit is added to the data byte.

2.) Ensures that the total number of 1-bits in the data byte plus the parity bit is even. 3.) Ensures that the total number of 1-bits in the data byte plus the parity bit is odd. |

| 9 | No. of Databits | 7/8 | Indicates that 8 data bits are used per byte, which is a common setting. |

| 10 | No. of Stopbits | 1/2 | Configures the serial communication to use 1 stop bit, which is a common setting ensuring the end of each byte is clearly marked. |

| Modbus protocol: TCP | |||

| 11 | Modbus Comm IP | Ex: 192.168.10.147 | IP of the device you are communicating with. |

| 12 | Modbus Comm Port | Ex: 502 (default) | Give a specified TCP port number |

| 13 | Modbus Comm Timeout | Ex: 60 | This refers to the maximum amount of time the master device will wait for a response from a slave device before it assumes a communication failure. |

| 14 | Start Register | Example: 0 | The start register indicates the address of the first register to be read in the slave device. |

| 15 | No. of Resister | Example: 10 | This specifies the number of consecutive registers to read starting from the start register. |

Register Config:

In this section you can add multiple parameters to read in ‘Default Mapping’ & ‘Custom Mapping’.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Default mapping | 1.) Tag Name = (Ex: FQ)

2.) Data type = Hexadecimal; Floating point| IEEE 754 (Swapped byte) | Floating point (Swapped Byte) | 16bit INT, high byte first | 16bit INT, low byte first | 16bit UINT, high byte first | 16bit UINT, low byte first | 32bit UINT (byte order 1,2,3,4) | 32bit UINT (byte order 4,3,2,1) | 32bit INT (byte order 1,2,3,4) | 32bit INT (byte order 4,3,2,1) |

1.) Input value name.

2.) Defines how read data will be stored. |

| 2 | Custom mapping | 1.) Register name:

2.) Start register: 3.) Register count: 4.) Data type =Hexadecimal; Floating point | IEEE 754 (Swapped byte) | Floating point (Swapped Byte) | 16bit INT, high byte first | 16bit INT, low byte first | 16bit UINT, high byte first | 16bit UINT, low byte first | 32bit UINT (byte order 1,2,3,4) | 32bit UINT (byte order 4,3,2,1) | 32bit INT (byte order 1,2,3,4) | 32bit INT (byte order 4,3,2,1) |

1.) Input value name.

2.) First register in custom register block. 3.) Path to file in which the custom register block will be stored. 4.) Defines how read data will be stored. |

In Register Config,

Click on ‘Add’ to add new parameters.

Click on ‘Show JSON’ to view an example value of how the data will be presented. Click on ‘Update Device’ once configuration changes have been made.

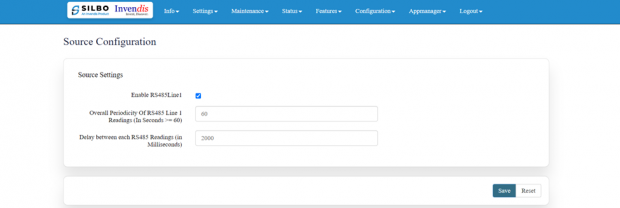

6.3 Data Source Configuration

These configurations ensure that the system regularly acquires data from various interface like RS485 at specified intervals, allowing for efficient monitoring and management of connected devices and sensors.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Enable RS485Line1 | Enable/Disable | This option enables the RS485 Line 1 interface for energy meter readings. |

| 2 | Overall Periodicity of RS485 Line 1 Energy meter Readings (In Seconds >= 60) | Value: 60 | Defines the interval in seconds at which readings are taken from the RS485 Line 1 energy meter. The minimum allowable interval is 60 seconds. |

| 3 | Delay between each Energy meter Readings (in Milliseconds) | Value: 2000 | Specifies the delay in milliseconds between individual readings from the energy meter on RS485 Line 1. |

Click on save once changes have been made.

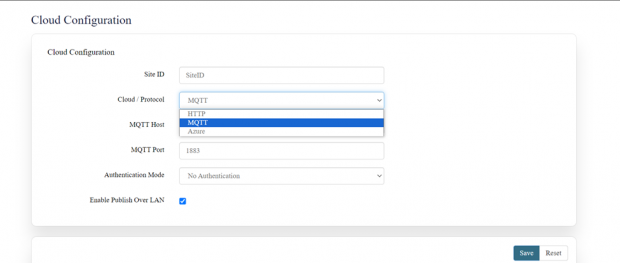

6.4 Cloud Configuration

In this section you can select the protocol by which you need to send data to cloud.

There are 3 Cloud/Protocol available,

HTTP

MQTT

Azure

HTTP Cloud/Protocol: This configuration sets up communication between your device and cloud service using the HTTP cloud.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Site ID | Ex: ‘Site123’ or ‘Device456’. | A unique identifier for your site or device within the cloud service. |

| 2 | Cloud / Protocol | HTTP | The protocol used for communication with the cloud service. |

| 3 | HTTP URL | Example: www.httpbin.org/post | The endpoint URL of the cloud service where data will be sent. |

| 4 | HTTP Port (Optional) | Leave it blank for the default port. | The port number for the HTTP connection. This is optional because the default port for HTTP (80) is used if not specified. |

| 5 | Enable Authentication | Enable/Disable | Enable this if your cloud service requires a username and password. |

| 6 | Username | Example: admin | The username for authentication with the cloud service. |

| 7 | Password | ***** | The password for authentication with the cloud service. |

| 8 | Enable Server Response Validation | Enable/Disable | Enable this if you need to verify that the server's response is valid. |

| 9 | Server Response | Ex: RecordID or custom | A unique identifier for the record being sent to the cloud service. |

| 10 | Method | 1.) Post

2.) Get |

1.) The HTTP method used for sending data to the cloud service.

2.) The HTTP method used for requesting data from the cloud service. |

MQTT Cloud/Protocol:

This configuration sets up communication between your device and a cloud service using the MQTT protocol.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Site ID | Example: ‘Site123’ or ‘Device456’. | A unique identifier for your site or device within the cloud service. |

| 2 | Cloud / Protocol | MQTT | The protocol used for communication with the cloud service. |

| 3 | MQTT Host | Example: broker.hivemq.com | The MQTT broker's address (hostname or IP address) that the device will connect to for sending and receiving messages. |

| 4 | MQTT Port | Example: 1883 | This is the default port for unencrypted MQTT connections. |

| 5 | Authentication Mode | 1.) No Authentication

2.) Username/Password 3.) TLS |

1.) Connect to the broker without any credentials.

2.) The Username/Password for authentication with the cloud service. 3.) Upload TLS certificates only if TLS authentication is selected as shown in the above image. |

| 6 | Enable Publish Over LAN | Enable/Disable | When enabled, the device will also publish MQTT messages over the local area network (LAN). |

| 7 | RS485 Topic (Optional) | Example: RS485Data1 | The MQTT topic for publishing RS485 data. |

| 8 | Command Request Topic (Optional) | Example: CommandRequest1 | The topic to which the device listens for command requests. Leave it blank if not in use. |

| 9 | Command Response Topic (Optional) | Example: CommandResponse1 | The topic on which the device publishes responses to commands. Leave it blank if not in use. |

Click on save once configuration changes have been made.

Azure:

This configuration sets up the connection to Azure IoT Hub using either MQTT or HTTP protocols with a specified connection string.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Site ID | Example: ‘Site123’ or ‘Device456’. | A unique identifier for your site or device within the cloud service. |

| 2 | Cloud / Protocol | Azure | The cloud service and protocol used for communication. |

| 3 | Protocol | 1.) MQTT

2.) HTTP |

1.) A lightweight messaging protocol suitable for IoT devices.

2.) A protocol used for communication over the web, commonly used for RESTful services. |

| 4 | Connection String | e.g., invendis-iot-hub.azure-devices.net. | The primary or secondary key used to authenticate the device with the IoT Hub. |

Click on save once configuration changes have been made

6.5 Send Configuration

Send configuration allows to choose type of string that should be sent to a cloud platform.

SILBO devices do offer 3 different options as shown below.

CSV (CSV allows fixed CSV)

Fixed JSON

Editable JSON. (JSON option is the editable JSON option)

Data sender Configuration is divided into major 2 parts,

JSON

CSV

JSON is further divided into 1 category,

Modbus Sender:

Select the field input you wish to add from the ‘Field Content tab’.

Give a desired JSON Key Name you wish to publish in the ‘Field JSON Key Name’ tab.

Once configured, click on Add.

JSON option allows editable JSON in which we can change which parameters should be sent and what name we should use to the tag.

What changes we can do in JSON edit to the above list.

Let’s change slave_id to some other name as “Slave number”.

Even custom fields can be added, for example if location name should be sent by router/gateway in JSON packet then it can be configured as shown.

CSV:

This option sends data packets in CSV (Comma-Separated Values) format.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Device ID | PC312 | A unique identifier for the device. |

| 2 | Record Start Mark | [ | This character marks the beginning of a data record. It's used to indicate where a new data record starts in the transmitted packet. |

| 3 | Record End Mark | ] | This character marks the end of a data record. It signals the end of the data for one record before a new one starts. |

| 4 | Register Start Mark | < | This character marks the beginning of a register within a data record. A register typically represents an individual data field within the record. |

| 5 | Register End Mark | > | This character marks the end of a register within a data record. It indicates where the data for a particular field end. |

| 6 | Invalid Data Character | N | Used to indicate that the data for a particular register is invalid or could not be collected. This helps in identifying which data points are not usable. |

| 7 | Failure Data Character | NA | Used to indicate that there was a failure in collecting or processing the data for a particular register. It signifies that an error occurred, and the data point could not be obtained. |

Click on save once changes are made.

7. Appmanager

Appmanager is a system utility that manages the installation, configuration, and execution of software applications on a device.

This section is divided into 8 categories,

- Application Start/Stop

- Application Software Upgrade

- Modbus Utility Configuration

- Import/Export Application Configurations

- App Health Status

- IO Utilities

7.1 Application Start/Stop

All changes made in ‘Configuration’ section should be saved into backend and to do that navigate to Appmanager>> Application Start/Stop.

Click on update to save all the changes made in configuration section.

Once updated click on start.

Make sure application is started to send data to cloud, once started it can be seen start option is replaced by Stop as shown above.

7.2 Application Software Upgrade

In this section you can upgrade software manually or automatically.

For auto upgrade, enable auto upgrade tab,

This is further divided into 2 sections,

Client and server settings

Auto Upgrade Interval

Specification details are given below:

| Client and Server Settings | |||

| SN | Field Name | Sample Value | Description |

| 1 | Authentication | Enable/Disable | Enable if username/password is required. |

| 2 | Username | XXXX | The username required to authenticate with the server. |

| 3 | Password | XXXX | The password required to authenticate with the server. |

| 4 | Server address | ftp://XXXX | The URL or IP address of the server where the upgrade files are located. |

| 5 | Connection timeout | Ex: 180 | The maximum time (in seconds) the system will wait to establish a connection with the server before timing out. |

| 6 | Operation timeout | Ex: 240 | The maximum time (in seconds) the system will wait for the upgrade operation to complete before timing out. |

| Auto Upgrade Interval | |||

| SN | Field Name | Sample Value | Description |

| 1 | Minutes | Example: 56 | Set the minute part of the interval when the auto-upgrade check will occur |

| 2 | Day Of Month | Example: all | Specifies the days of the month when the auto-upgrade check should occur. |

| 3 | Month | Example: all | Specifies the months during which the auto-upgrade check should occur |

| 4 | Day Of Week | Example: all | Specifies the days of the week when the auto-upgrade check should occur. |

You can also check the current software version and manually upgrade software as shown below.

To Manually upgrade Application,

Enter the correct ‘Checksum’ and ‘Size’ and upgrade the page.

(Please stop the applications before upgrading)

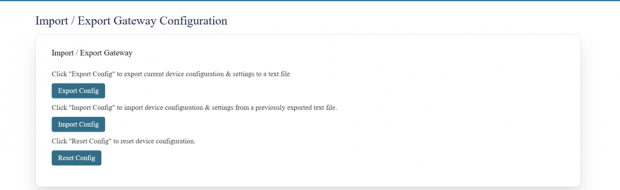

7.3 Import / Export Gateway Configuration

This functionality ensures that you can easily manage, back up, and restore device gateway

configurations, as well as reset the device to default settings when needed.

Export Config:

Usage: Click the "Export Config" button to save the current configuration to a file.

Import Config:

Usage: Click the "Import Config" button and select the text file containing the configuration you want to import.

Reset Config:

Usage: Click the "Reset Config" button to revert the device to its default configuration settings.

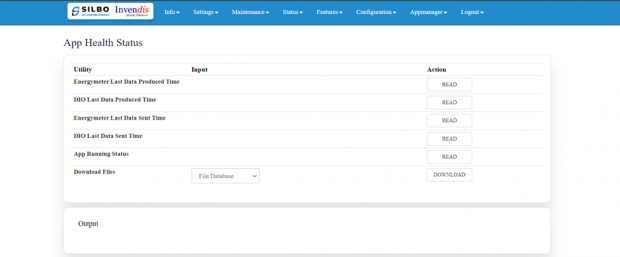

7.4 App Health Status

This section provides utilities to check the health and status of various applications and data inputs

within the system. It allows monitoring of the last data produced and sent times for different utilities, as

well as the running status of applications.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | Energymeter Last Data Produced Time | Command ‘Read’ | Displays the last time data was produced by the energymeter. |

| 2 | DIO Last Data Produced Time | Command ‘Read’ | Displays the last time data was produced by the digital input/output system. |

| 3 | Energymeter Last Data Sent Time | Command ‘Read’ | Displays the last time data from the energymeter was sent. |

| 4 | DIO Last Data Sent Time | Command ‘Read’ | Displays the last time data from the digital input/output system was sent. |

| 5 | App Running Status | Command ‘Read’ | Displays the current running status of applications. |

| 6 | Download Files | Command ‘Download’ | Choose the desired option from the dropdown menu.

Download data or logs related to the options available. |

| 7 | Output | Display Value | Provides output or feedback based on selected utilities. |

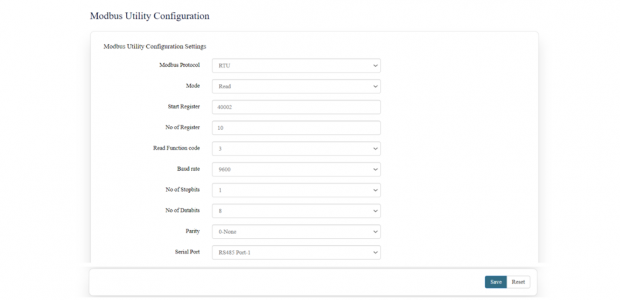

7.5 Modbus Utility Configuration

Any changes to be made in Modbus Configuration to test can be made in Modbus Utility Configuration without disturbing the actual Modbus Configuration.

The working process of ‘Modbus Configuration’ and ‘Modbus Utility Configuration’ are same.

Refer (6.5 Modbus Configuration) for specification details.

Click on save once configuration changes have been made.

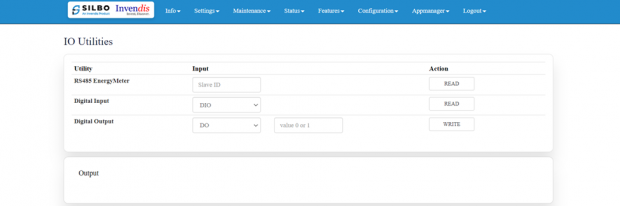

7.6 IO Utilities

This section provides output of various utilities connected to the device.

This section exactly shows whether the connection made is successful or not.

Specification details are given below:

| SN | Field Name | Sample Value | Description |

| 1 | RS485 EnergyMeter | Input: Slave ID | Action: Manage RS485 energy meters by specifying the slave ID. |

| 4 | Digital Input (DIO) | Input: Select from 1, 2, 3, 4 | Action: Manage digital input settings. |

| 5 | Digital Output (DO) | Input: Select from 1, 2, 3, 4 and specify the value (0 or 1) | Action: Manage digital output settings. |

| 7 | Output | Print any values | Action: Will display the results or status messages based on the actions performed using the utilities. |

8.Logout

The user should click on log out option to logged out from the router application.